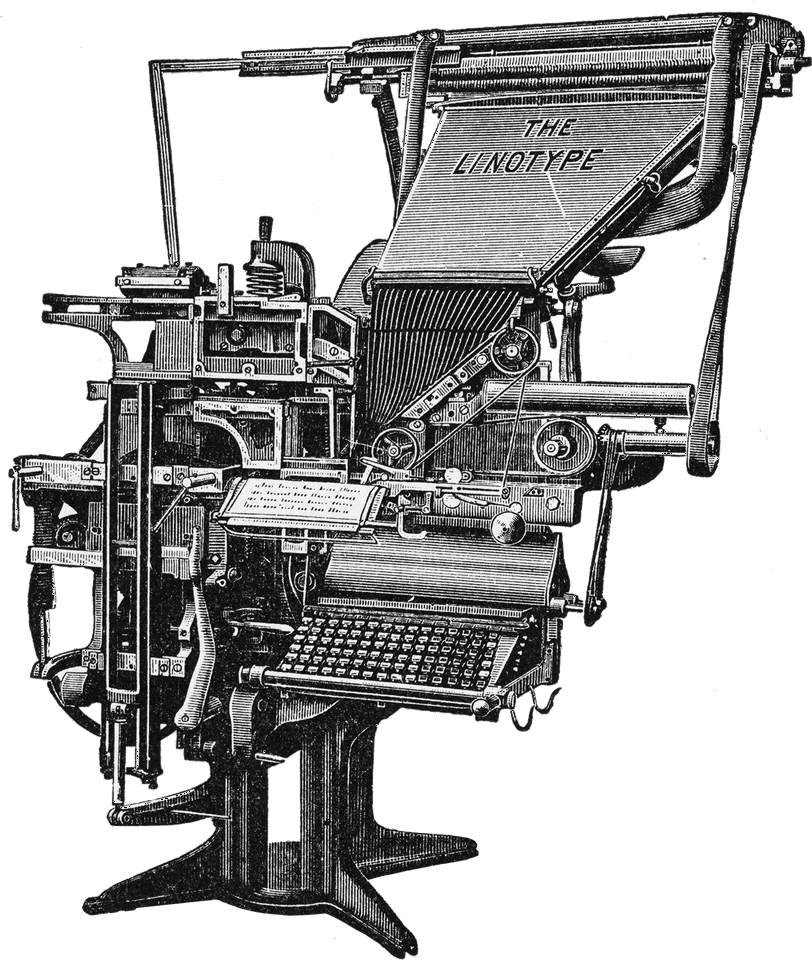

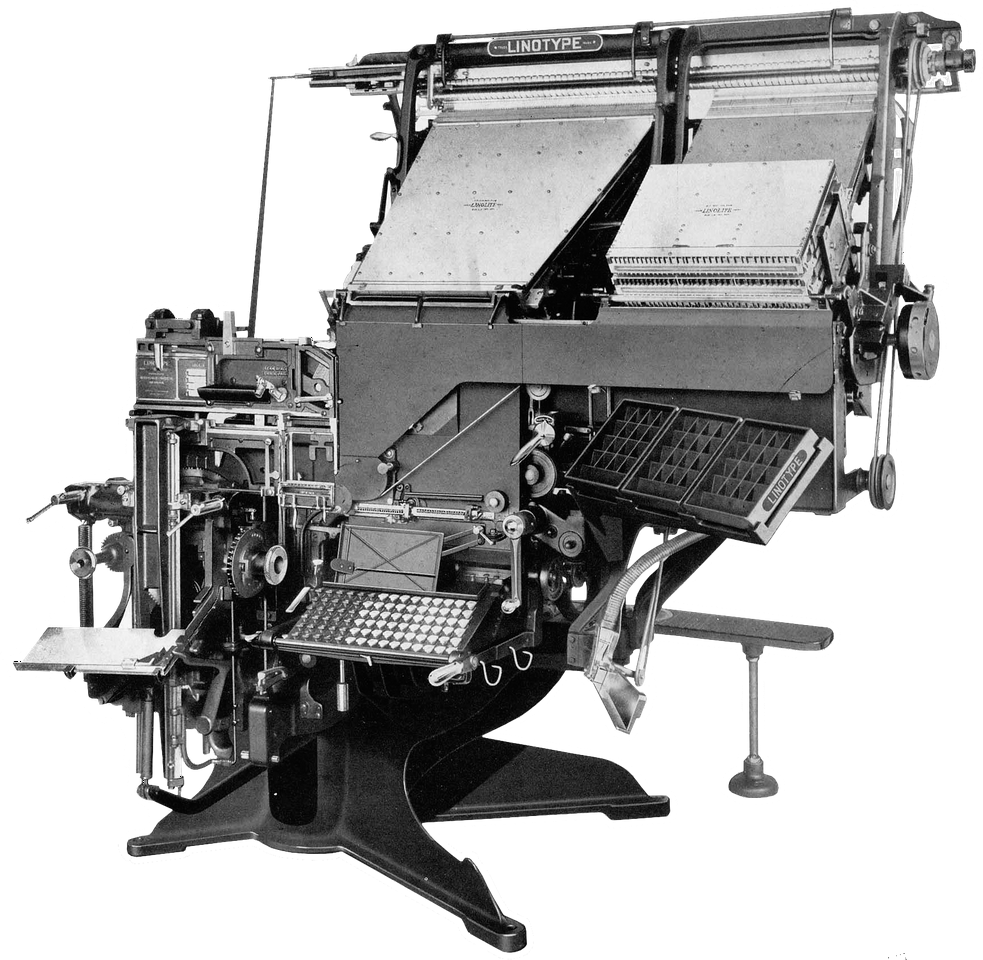

Model 1 | 1892

Replaced in February 1902 by the Model 3.

The Model 1, the first truly successful Linotype, was introduced in 1892. About 6000 were sold throughout the world. The machines chief characteristic was its narrow magazine. Because the magazine was narrow, its range was limited to matrices not larger than 11 point because the channels the magazine were so close together that there was not space enough for thick matrices to slide down side by side. Its magazine was not of the quick change type: It could be changed from the rear, but the operation required the services of two men, was hard work and took about an hour. The Model 1 was inaccessible. It was difficult to get at and replace the cams, keyrods, verges, etc., and breakages at busy moments often resulted in expensive losses of time.

The Model 1 had the old style channel entrance-that is, a channel entrance was attached to each magazine. The magazine was not interchangeable with that of any other model.

The machine sold for $3150, and was leased for six-year periods at an annual rental of $550.

Surviving Machines:

#160SJ, #5757Model 2 | 1903

Replaced in March 1906 by the Model 4.

The Model 2 was the first two-magazine machine.

It was not as successful as some of the other models, chiefly because its double magazine mechanism was complicated. Many of the Model 2’s had the lower magazine out of use entirely or it was used only rarely for headlines, etc., and not for straight composition.

In selling double magazine machines, particularly the Model 4, Mergenthaler, salesmen often contended that the lower magazine was practically as fast as the upper. This contention was not entirely true as any operator knows and as anyone could understand after seeing the machine in operation. The assembling of lower magazine matrices was necessarily slow; because they had to first travel along a horizontal matrix delivery belt and then slide, one by one, down a chute leading to the assembling elevator. Besides, the matrices in the course of their long journey to the assembling point were apt to clog, either on the horizontal matrix delivery belt or in the chute. In either case it was difficult to get them out.

The change from one magazine to the other was practically instantaneous, unless something went wrong, being accomplished by the movement of a small lever at the operator’s right.

The upper magazine could be removed from the rear, by two men, but it was a difficult and time-consuming task.

The lower magazine was several inches shorter than the upper, holding only sixteen matrices instead of the usual twenty. This, of course, greatly reduced the speed of this magazine, particularly on wide measures, because the operator was frequently forced to wait for one line to partially distribute before he call set the next.

The escapements of both magazines were actuated by one set of keyrods. This was made possible by having the lower magazine verges on top of the magazine instead of below it. When the upper magazine was in operation the lower magazine escapements were locked, and vice versa, this locking and unlocking being the function of the lever by which the operator made the change.

Distribution on the Model 2 was automatic that is, the matrices from both magazines could be mixed in the same line, if desired, and the distributing mechanism will separate them. There were two separate distributors-two boxes, two rails and two sets of screws. Lower magazine matrices pass through the upper distributor box, but instead of passing on to the upper rail they dropped through a chute to the lower box, from which they passed to the screws in the usual manner. The separation of the lower magazine matrices from the upper, in the upper distributor box, was effected by means of a large beveled notch cut out of the bottom of each lower magazine matrix. Matrices having this beveled notch could be run in an upper magazine or in a single magazine machine by use of a special attachment, but matrices without the beveled notch cannot be run in a lower magazine.

Faces smaller than 8 point were particularly troublesome in a lower magazine because of their lightness. The upper magazine had the old style channel entrance and was interchangeable with the Model 3 magazines of that kind. The lower magazine of Model 2 was not interchangeable with that of any other model. There were no special differences between the casting mechanism of the single and double magazine machines.

The Model 2 sold for $3600. It was superseded by the Model 4, another double magazine Linotype, having so-called “quick change” magazines and other improvements.

There are no known surviving machines of this model.

Model 3 | 1902

Superseded in 1906 by the Model 5.

This was the second single magazine model. It was often called “the pica machine,” because it was the first having a magazine wide enough to accommodate 12 point and larger faces. Comparatively few Model 3’s were sold, because the machine was soon superseded by the Model 5.

Some Model 3’s have the old style channel entrance-that is, the channel entrance was attached to the magazine.

These magazines were interchangeable with the upper magazine of Model 2. Later Model 3’s carry the new style channel entrance-one channel entrance, attached to the machine, serving for all magazines. Magazines of the latter class were not interchangeable with those of any other machine.

A few rebuilt Model 3’s have been sold, and quite a number have been rebuilt into Model 5’s both in the Linotype factory and by outsiders. The latter practice was discouraged until the coming of the Intertype, and they still prefer to accept the old machine in part payment toward a new one of the later model.

The price of the Model 3 was $3150.

There are no known surviving machines of this model.

Model 4 | 1909

All statements made in the preceding paragraphs under the heading “Model 2 Linotype,” beginning with the second paragraph, apply also to the Model 4, excepting those regarding the removal of magazines. There were also a few minor differences between the two models.

The Model 4 was the first “quick change” double magazine Linotype. its upper magazine was removable from the front, and one man could make the change. On the Model 4 it was necessary to lock the matrices in, this being accomplished by thrusting a small locking bar through the bottom of the magazine. This does not require much time unless the locking bar was stopped by some matrix which had stuck in the bottom of the magazine. After getting the locking bar in place the operator must raise the bottom of the magazine a few inches, by means of two levers at the sides of the machine, when it was possible to slide the magazine down and off.

The lower magazine was removed from the rear, and it was possible to change it while the upper magazine was in use. This feature was much talked about by the Linotype people. The Model 4 lower magazine was short, like that of Model 2.

The machine carried an automatic sorts stacker and a water cooled mold disk as standard equipment. The latter was added only after the beginning of Intertype competition. The lower magazine distributor was somewhat more accessible than that of Model 2. The upper magazine was interchangeable with those of Models 5. 6, 7 (upper), 8, 11, 14, 18 and 19; the lower magazine was interchangeable with the lower magazine of Model 7.

There are no known surviving machines of this model.

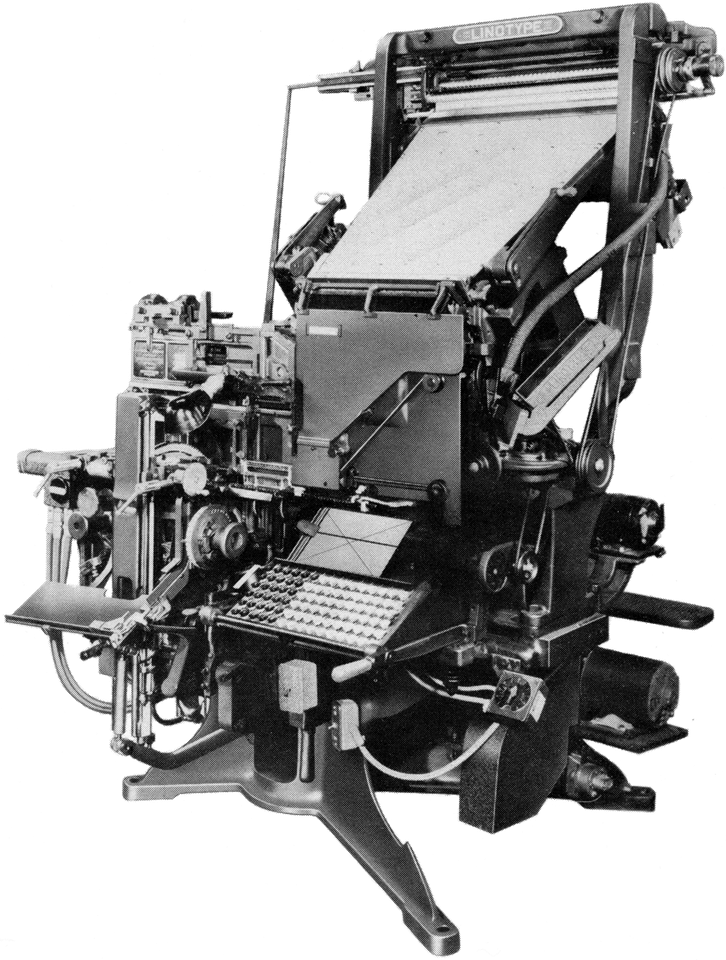

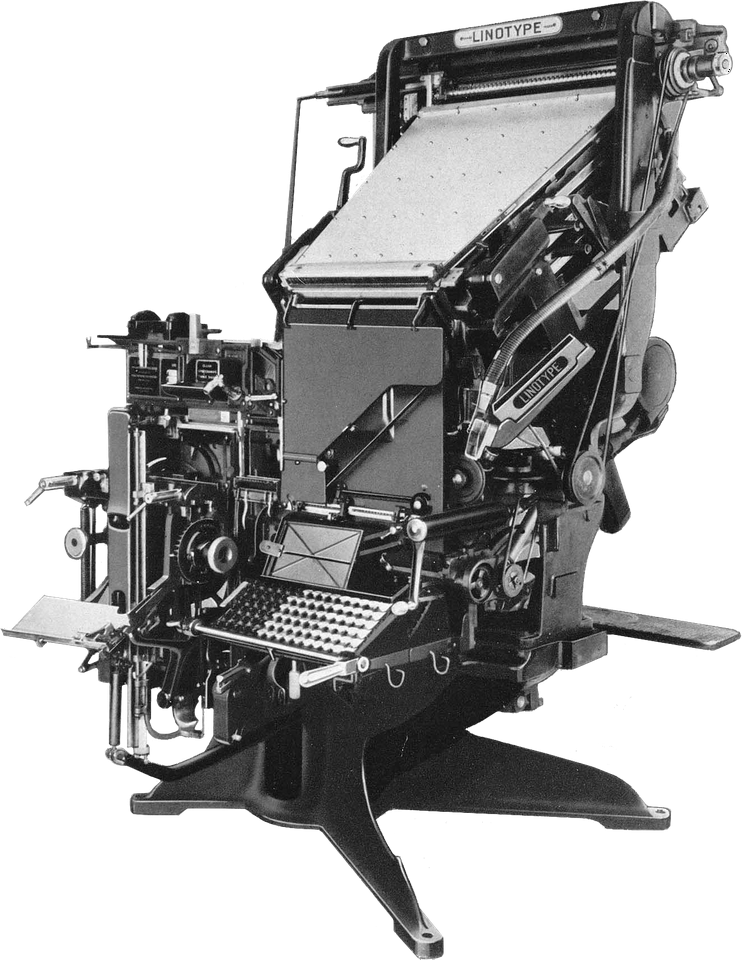

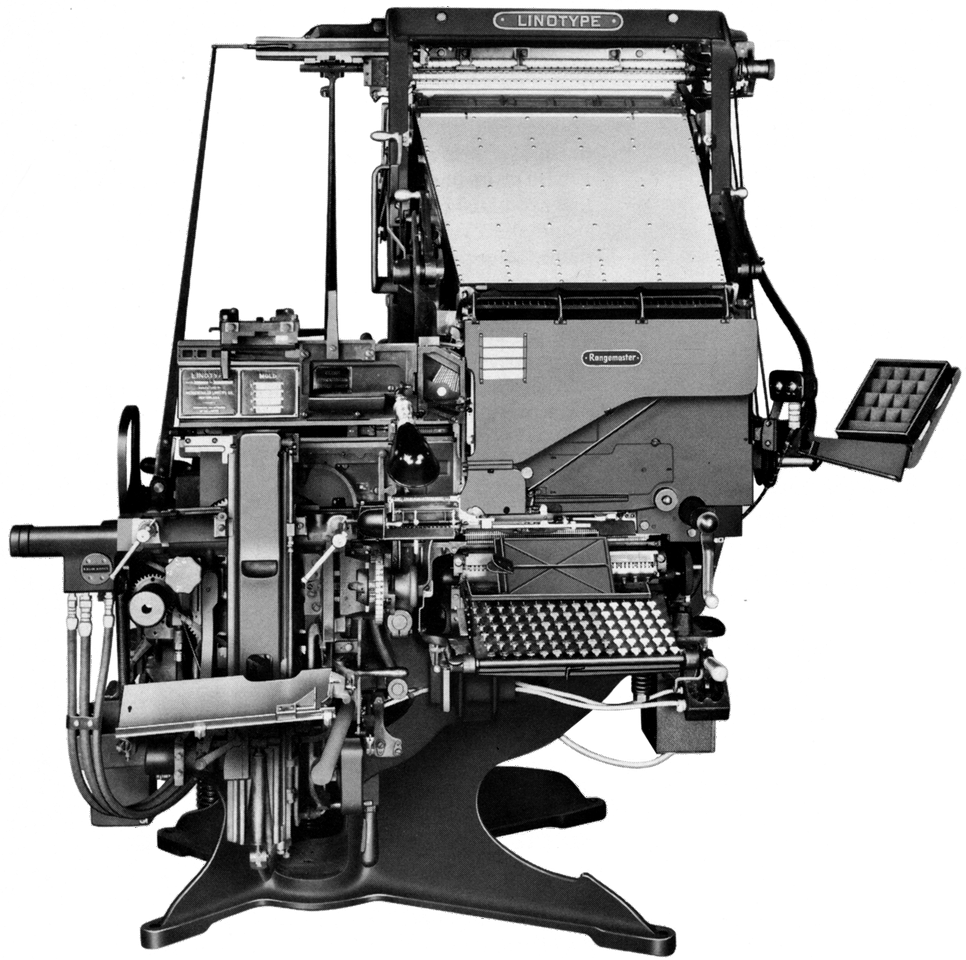

Model 5 | 1906

Introduced February 1906.

This machine was very similar to the Intertype, with “A” Equipment. It was the Linotype Company’s first “quick change” single magazine model.

The magazine of the Model 5 was removable from the front in the same manner as the upper magazine of the Model 4. The machine carried an automatic sorts stacker and a water cooled mold disk as standard equipment when specified, these features having been added since the Intertype was introduced.

Used and Rebuilt Model 5’s

Attention was called to the fact that some tired or rebuilt Model 5’s carry a factory number below that of the first Model 5 which was shipped from the Linotype Factory. This was conclusive evidence that the machine originally was either a Model 1 or Model 3. The first Model 5 was No. 9851 and was shipped in February 1906.

Keep this in mind, and, when in competition with a used or rebuilt Model 5, caution the prospect in a pleasant way to see that the factory number of the Model 5 offered was not below No. 9851.

Surviving Machines:

#8541, #9857R, #10110, #10659, #11139, #12497, #12828, #13213, #15152, #16007, #23691, #26532, #33378, #35920R, #37969R, #41786, #42543R, #57497, #66064, (Missing Serial Number), (Missing Serial Number), (Missing Serial Number), (Missing Serial Number), (Missing Serial Number), (Missing Serial Number), (Missing Serial Number)Model 5E | 1939

Model 5F | 1945

Model 6 | 1908

This machine was simply a wide measure Model 5-that is, it will cast slugs up to 36 ems wide instead of up to 30 ems.

There are no known surviving machines of this model.

Model 7 | 1907

This machine was simply a wide measure Model 4 - that is, it will cast slugs up to 36 ems wide instead of up to 30 ems.

There are no known surviving machines of this model.

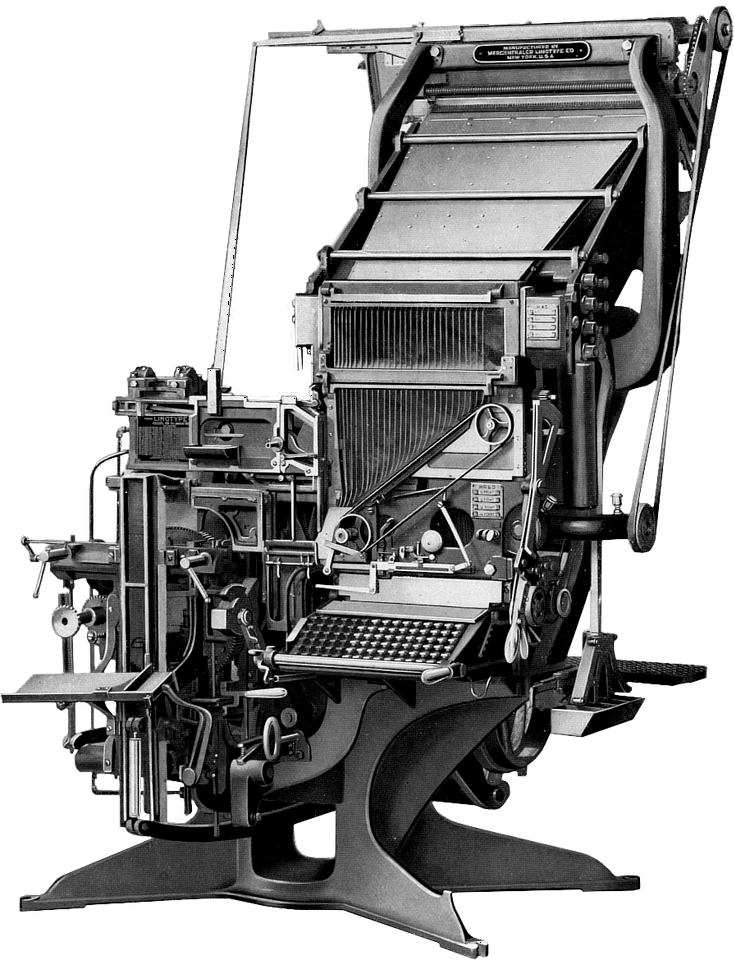

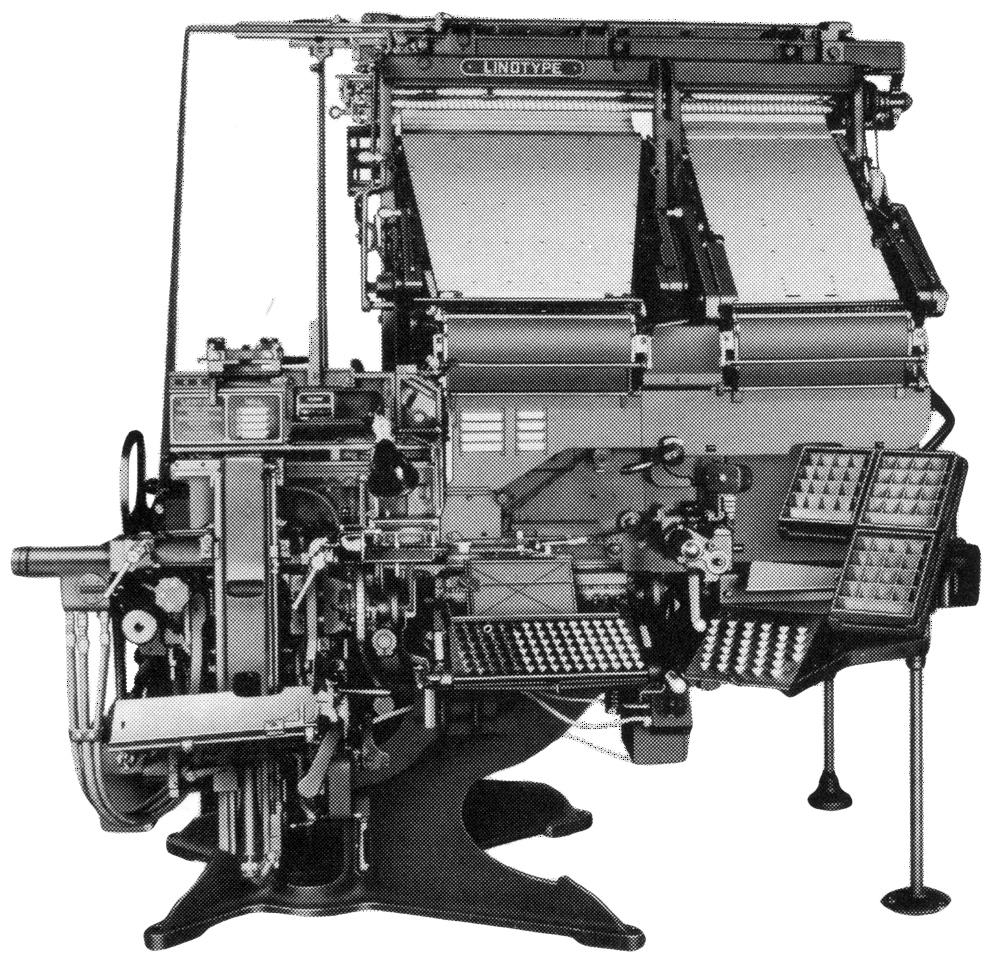

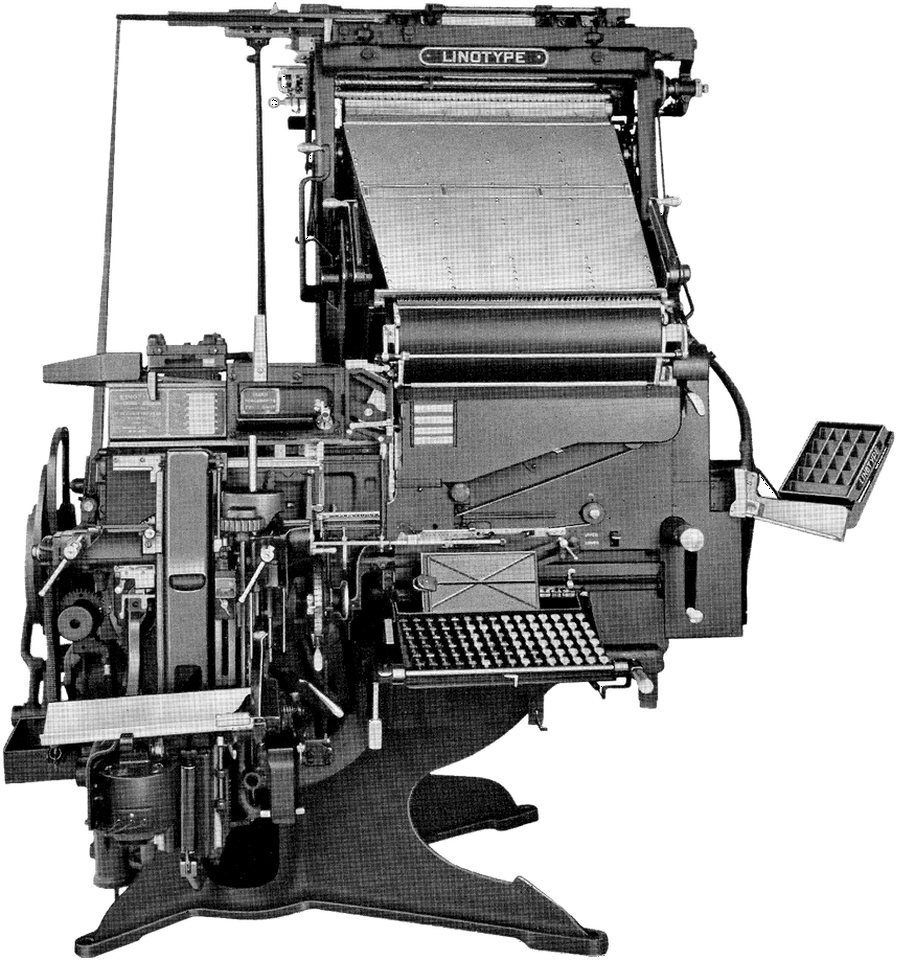

Model 8 | 1911

The Model 8 three-magazine and Model 9 four-magazine Linotypes were brought out simultaneously in 1911. Both have been pushed hard, and a large number of them were now in operation.

The Model 8 carried three superimposed magazines. These rest in a movable frame which could be raised of, lowered by the operator to bring any one of them into operative position. One distributor serves for all three magazines; consequently, it was necessary to wait for all the matrices of one magazine to distribute before changing to another.

The escapement mechanism was complicated. To make the connection between any one of the three sets of escapements and the one set of keyrods, ninety crescent-shaped operating levers were necessary. These were pivoted at one end, actuated by the keyrods in the middle and act upon the escapements with the other end. These ninety extra moving parts and the lost motion which they involve, constitute one of the objections to the Model 8. Not only were there more parts in each train of connections between the keyboard and the escapement verge, but the action was harder, owing to stiffer escapement springs and the short leverage at which the verge was actuated.

All of the magazines of this machine were alike and interchangeable with each other and with the magazines of Models 4 (upper), 5, 6, 7 (upper), 11, 14, 18 and 19. The top magazine was removable from the front, as on the Model 5. but not quite as easily. To remove the middle magazine the upper escapement block must be removed from the machine and the upper magazine and its frame jacked up.

The lower magazine was no more removable than the pot jacket; it was easier to run the matrices out and run in another set. The fact that this third magazine was not easily removable was a serious fault of the Model 8. Linotype salesmen get around it by stating that every office had at least one face which must always be kept on the machine, and that this face could be run in the third magazine.

To change from one to another of the three magazines carried by the Model 8 the operator turns a small wheel, provided with a convenient handle, located at his right. Ten revolutions of the wheel made the change from one magazine to the next. Twenty revolutions were necessary in changing from the first to the third magazine, or vice versa. At the beginning of each change, two automatic safety devices come into play. One was a strip of metal which slips down over the bottom of the magazine and warns the operator if any matrix was projecting. The other was a similar strip which passes in against the distributor bar, between the screws, and warns him if any matrices were on the bar. it was impossible to make a change of magazine, if everything was working properly, until both the distributor bar and the bottom of the magazine were clear.

All of these extra parts were apt to get out of order. Sometimes a matrix projects from the bottom of the magazine and the safety device falls to work. Then if the magazines are, descending, the offending matrix may get caught in such a way as to raise one of them from its escapements. In such a case all of the matrices in that magazine at once slide out on to the floor. If there were matrices on the distributor bar when the change was started, and the safety guillotine falls to work, the result was a number of troublesome wrong fonts.

The casting mechanism of the Model 8 was exactly like that of any Linotype. Equipment included in the machine’s price consists of three magazines, three fonts of matrices, three molds, water cooled disk, and sectional universal ejector.

Surviving Machines:

#16625, #19208R, #24885, #27008, #27018R, #27036, #28884, #28888, #29040, #29760, #30880, #31166, #31286, #31963, #33441, #33679, #33894, #33931, #35151, #35410, #35964, #36706, #41914, #42227, #43917, #44124, #45418, #46710, #46738, #46773, #49124, #49577RR, #50958, #52136, #54424, #55875, #56007, #56138, (Missing Serial Number), (Missing Serial Number), (Missing Serial Number), (Missing Serial Number), (Missing Serial Number), (Missing Serial Number), (Missing Serial Number), (Missing Serial Number), (Missing Serial Number), (Missing Serial Number), (Missing Serial Number)Model 9 | 1911

The Model 9 was the most complicated of all the Linotype models.

This machine carried four magazines. These do not move up and down, as on the Model 8. They were all removable from the front, the change requiring four or five minutes, and were interchangeable with each other but not with those of any other models.

The assembling mechanism was cumbersome. The connection between the one set of keyrods and the four sets of escapements was made by a set of ninety straight rods, which could be moved up and down to engage with the escapements of any of the magazines. It was by shifting these connecting rods that the change of magazine was effected, the operation being performed by a ]ever at the operator’s right.

The same spaceband release was used with all the magazines, and this was the source of another difficulty. Since the magazines lay one above the other, and do not move up and down, it was obvious that matrices from the top magazine cannot drop to the assembling elevator as quickly as matrices from the bottom magazine. Simply because they have several inches further to drop. Consequently, matrices from the bottom magazine were apt to get down ahead of the spaceband, although released after the spaceband was touched. Likewise, matrices from the top magazine often arrive after the spaceband was in the assembling elevator although released before it. It was impossible to remedy this difficulty, as the spaceband release could be timed for only one of the four magazines.

The faceplate of the Model 9 could be swung back to expose the top of the keyrods, the connecting rods, and the bottoms of the magazines. This must be done in order to remove a magazine.

The complications of the Model 9 distributor were such as to make the machine a source of much trouble in some shops. There were four distributor rails, four sets of screws, and five distributor boxes. The first distributor box was called the primary distributor. its function being to direct the matrices to the distributor accompanying the magazines in which they belong. This was accomplished by means of small bridges placed in the primary distributor, over which the matrices ride or straddle according to the way they were notched. When a matrix reaches the proper point in the primary distributor it falls down a chute to the distributor box of the magazine in which it belongs, when it, was distributed in the usual manner. When one of the four distributors stop, they all stop. To reach one distributor it, was necessary to lift. the heavy frame which supports them all. The four sets of channel entrances were also all in one frame and all must he raised together to reach the top of any of the magazines.

Surviving Machines:

#33583, (Missing Serial Number)Model 10 | 1911

This was a small single magazine machine, designed for offices unable to pay the Linotype Company’s high price for a Model 5. It was no longer manufactured, having been superseded by Model 15. As an excuse for placing a comparatively low price upon it, and at the same time to prevent its interfering with the sale of higher priced machines, the Model 10 was given certain limitations, both as to speed and range. Its magazine will hold only fourteen matrices to the channel instead of the usual twenty. This so reduces its speed that it could never be sold to any but very small shops. The range of the Model 10, like that of Model 1, was limited to faces not larger than 11 point.

Surviving Machines:

#15724Model 11 | 1911

This machine was simply a wide measure Model 8-that is, it will set slugs up to 36 ems wide, instead of up to 30 ems.

There are no known surviving machines of this model.

Model 12 | 1912

This machine was simply a wide measure Model 9

There are no known surviving machines of this model.

Model 14 | 1914

This machine was first exhibited at the Waldorf-Astoria Hotel, New York, in April 1914. It was very similar to the Model 8, having three magazines, a Model 8 changing mechanism universal ejector, water cooled mold disk etc.

The main feature of the machine was a narrow auxiliary magazine, placed besides the three regular magazines and in a plane with them. The matrices contained in this auxiliary magazine were released by means of an escapement mechanism connected directly (that is, without a keyboard cam action) to a series of key buttons, somewhat like those, on an adding machine, but arranged vertically. The distributor bar of the machine and the distributor screws were elongated to cover the auxiliary magazines. The latter contains twenty-eight channels. Besides using ordinary Linotype matrices, it could carry large display characters up to 42 or 48 point set-wise. These large matrices have of lugs, and thus each character occupied two channels. The machine was designed to set headletter or large advertising figure display composition in connection with its regular work. Since the matrices from the auxiliary magazine must be carried to the assembling mechanism by means of an auxiliary matrix delivery belt, it was obviously impossible to assemble them at any considerable speed particularly large characters. Many operators prefer to assemble the matrices by hand from an automatic sorts stacker, and either lift them from the second elevator by hand or allow them to run down to the stacker. The auxiliary magazine could be changed very readily, and there was a rack fit the rear of the machine for carrying extra magazines, The auxiliary keyboard was a punch-board with two sets of key buttons, superimposed, so, that it change from one to the other could be made very easily.

Surviving Machines:

#19089, #22010, #23992, #25000, #25798, #28585, #28743, #28964, #29915, #30152, #34128, #34264, #34574, #34790, #35383, #35412, #35633, #36035, #36044, #36100, #36194, #36866, #42687, #46487, #47369R, #47491, #48710, #49890R, #49981, #52035, #54070, #55518, #55739, (Missing Serial Number), (Missing Serial Number), (Missing Serial Number), (Missing Serial Number), (Missing Serial Number), (Missing Serial Number), (Missing Serial Number), (Missing Serial Number), (Missing Serial Number), (Missing Serial Number), (Missing Serial Number), (Missing Serial Number)Model 15 | 1913

This machine superseded the Model 10. It had the same kind of a short magazine, removable from the front and limited to 14 matrices to the channel. It will carry faces from 5 point to 14 point, inclusive, and the Linotype Companies circulars state that at a slight additional cost it may be equipped to carry faces up to 36 point.

Surviving Machines:

#18250, #18262, #18266, #18449, #19775, #19858, #22517Model 16 | 1916

This was a two-magazine machine resembling in a general way, the Model 9, but having special magazines which were not interchangeable with the 9 or with, any other machine.

The magazines do not move up and down in a frame as on Models 8 and K. To change from one magazine to the other the operator presses a key at the right of the keyboard and the Mergenthaler advertising states that the change was so quick that operation from both magazines was continuous. Both magazines were of standard length, and were about three inches wider than any linotype magazines heretofore made. The increased width was necessary to allow the matrices from the lower magazine to pass between the keyboard rods.

Distribution was accomplished in about the same way as on the Model 9. The matrices first pass through a primary distributor, which separates them and allows them to drop through to the distributor box of the magazine in which they belong.

Surviving Machines:

(Missing Serial Number)Model 17 | 1916

This machine was similar to Model 16, but carried the auxiliary magazine attachment. Its regular magazines were wider than standard, for the reason noted under “Model 16 Linotype (Mixer).” As on the Model 14, the auxiliary magazine carried twenty-eight channels, which were used for matrices of any size, including condensed caps, fonts of large display faces, accented characters, advertising figures, headletter, etc. As on the Model 14, the auxiliary magazine keyboard was a punch-board with one set of keys placed over the other in such a way that two layouts for the auxiliary magazine could be on the machine at the same time. The auxiliary magazines were removed from the front, and there was a rack at the rear of the machine for storing three extra magazines. The auxiliary magazines were also interchangeable with those used on Models 14 and 19.

There are no known surviving machines of this model.

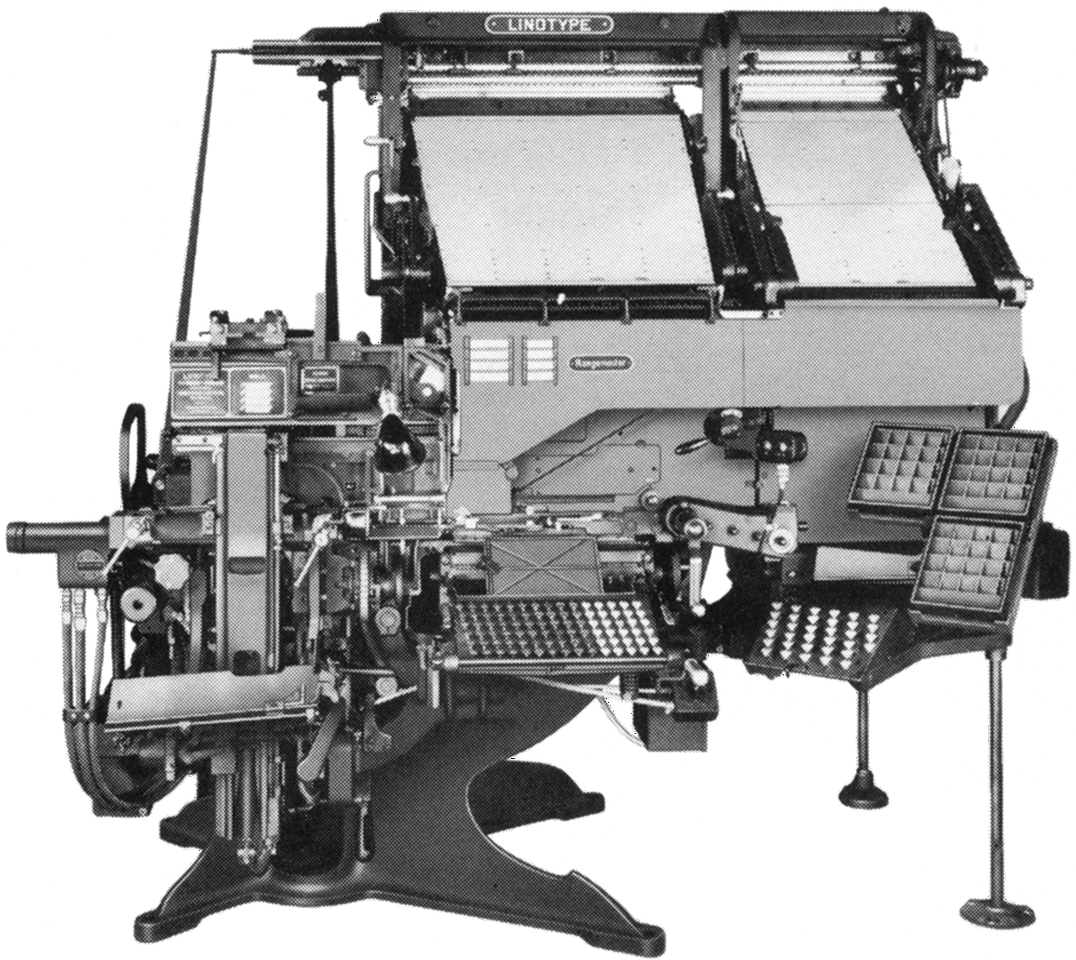

Model 18 | 1916

This was the two-magazine Model 5, its magazines being interchangeable with those used on Model 4 (upper), 5, 6, 7 (upper), 8, 14 and 19. Changes of magazine were made in the same way as on the Model K Linotype, and the magazines were independently removable from the front of the machine. The machine carried the sectional universal ejector, water-cooled mold disk, universal knife block, and double deck sorts stacker.

Surviving Machines:

#21313, #22684, #23211Model 19 | 1916

The Model 19 was simply a Model 18 with the auxiliary magazine attachment. Matrices from the auxiliary magazine could be mixed in the same line with matrices from either one of the regular magazines, but all must be distributed before a change of the regular magazines was made.

There are no known surviving machines of this model.

Model 20 | 1918

The Model 20 was a single magazine display machine, patterned after the Model 5, with a magazine carrying seventy-two (72) channels and a keyboard of seventy-two (72) keys. It will not set a face larger than a fat 24 point. The magazines were only half the length of the standard magazines.

There are no known surviving machines of this model.

Model 21 | 1921

Model 21 was a single magazine machine which accommodates either full-length or split magazines of seventy-two channels. The same as those used on the Model 20. The keyboard had seventy-two keys. The machine was equipped with two channel entrance frames, one of which could be swung out of and the other into operative position. When setting faces no larger than those carried on the Model 20, the machine was operated just as was the Model 20. To set faces beyond this range, that is, up to full 36 point, the channel entrance frames were shifted, and a lever at the side of the keyboard was moved. The movement of the lever automatically locks seventeen of the keys which leaves fifty-five of them in the operative position. In setting these extended faces, fifty-five of the magazine channels were used. A matrix galley attached to the face of each magazine accommodates sorts characters.

Surviving Machines:

#46901, #66310Model 22 | 1920

Model 22 was substantially the same as Model 21, with the addition of an auxiliary attachment which accommodates the characters that run as sorts on the Model 21. Auxiliary magazines also accommodate full sets of advertising figures or complete headletter fonts of twenty-eight characters. The auxiliary keyboard was located at the right of the main keyboard. Auxiliary magazines were interchangeable with all other Linotype auxiliary magazines of twenty-eight channels.

The full length magazines of both models provide full channels of text matrices.

There are no known surviving machines of this model.

Model 24 | 1921

The Model 24 was equipped with four molds.

The Model 24 Linotype was placed on exhibition in New York in April 1920.

The Model 24 Linotype was conceived as a display composing machine and was offered to the trade as the latest development in the art for text and ad display composition, up to a wide 36 point face. It was a further extension of the Model 9 and carried four magazines in its main magazine construction and four magazines in its side magazine construction.

On close investigation it was found that this Model 24 Linotype was of a very complicated construction.

There are no known surviving machines of this model.

Model 25 | 1924

This was a two-magazine mixer machine, resembling in a general way the Model 16. but using, as their advertisement claims, Model 5 magazines fit either the upper or lower position. Magazines may be split or full length, in either or both positions.

In order to bring the magazines in operating position, the shift lever was placed in a convenient position for use by the operator.

Distribution was accomplished by the use of two distributors, the matrices first passing through a primary distributor and the separation was accomplished by an extra cut in the bottom of the matrix.

The claim was made that all Linotype matrices will run in this machine if this extra cut in the matrix was provided.

In 1927, a new design of distributor box was introduced. The change was in the upper or primary box only, which had been made very much like old Model 2. The lower box remains the same.

With this change Models 25 and 26 compare with Model 4, except that the shift on Model 4 was much more simple.

This model was also offered to the trade as a 72-90 channel machine.

Surviving Machines:

#49043Model 26 | 1924

This machine was similar to Model 25, but carried two auxiliary magazines, one over the other, and the claim was made that the auxiliary magazines were interchangeable with the auxiliary magazines of Models 14 and 22. Main magazines were interchangeable and may be either split or full length.

Mixing was accomplished in the side magazines, in the same manner as in the main magazine and there was a similar shift for moving the side magazine, as in the case of the main magazines in order to bring the magazine into operating position.

In other words, the range of face claimed for this machine was similar to that of the Model 14.

On this machine only one keyboard was provided, and the method of securing matrices from the side magazines was accomplished in the same manner as in the Model 14. The same complications apparent in the side unit mechanism of the Model 14 and 22 ate found in this machine.

This model was also offered to the trade as a 72-90 channel machine.

All machines with higher serial numbers than 46700 (approximate) were equipped with wide 34-channel side magazines. This type of side magazine was not interchangeable with the so-called narrow, 34-channel type.

Surviving Machines:

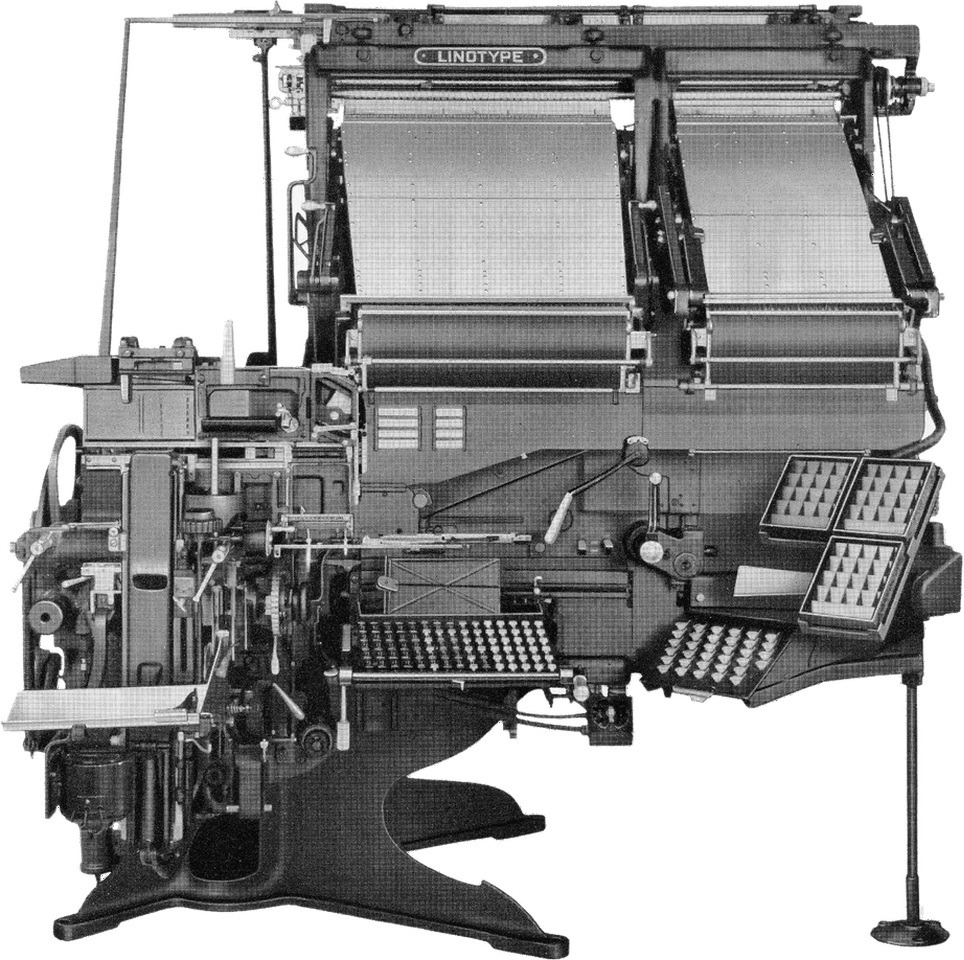

#36795Model 27 | 1935

This was a one, two or, three main-magazine machine equipped with extra wide 72-channel lightweight split magazines similar to our three-magazine Model 11. Tire magazines were 5% incites wider than the old style 72-channel magazines, and could be altered to interchange with Models 33, 34, 35, and 36. It was claimed that this machine will carry normal 36 point and condensed faces up to 60 point. Twelve matrices to the split magazine. It was a single distributor machine.

There are no known surviving machines of this model.

Model 28 | 1935

This machine was similar to the Model 27 but carried one or three wide side magazines like the Intertype Models H-1s.m. or H-3s.m.

One keyboard was provided for both main and side magazines, and the method of securing matrices front the side magazine was accomplished in the same manner as on the late Model 14.

There are no known surviving machines of this model.

Model 29 | 1937

Introduced November 1936.

This machine was a four main-magazine mixer, comparable to the Intertype F and G F4 and G4, with magazine equipments and mixing possibilities as follows:

One 72 and one 90, mix from both magazines. Two 72, mix from both magazines. Two 90, mix from both magazines. One 90 and two 72, mix from first two only. Two 90, one 72, mix from first two only. Three 90, mix from first two and bottom two. Three 72, mix from first two and bottom two. Four 72, mix from first two, second two and bottom two. Four 90, mix from first two, second two and bottom two. Two 72 and two 90, mix from first two and bottom two.

Surviving Machines:

#51294, #52539, #56778, #60597, #63282, #66592, #67313, #68326, #69034, #70110, (Missing Serial Number)Model 30 | 1937

This machine was similar to the Model 29 but carried two. three or four side magazines. Mixing of side magazine matrices was accomplished in the same manner as in the main magazine shift.

Following was a list of possible magazine equipment which is similar to Intertype two and four-magazine F-4s.m. and G-4s.m.:

- One 72 and one 90, with two side magazines, mixing both magazines.

- One 72 and one 90, with four side magazines, mixing both magazines.

- Two 72, with two side magazines, mixing both magazines.

- Two 72, with four side magazines, mixing both magazines.

- Three 72, with three side magazines, mixing first two and bottom two.

- Four 72, with two side magazines, mixing first two, second two and third two.

- Two 72 and two 90, with two side magazines, mixing from first two and bottom two.

- Two 72 and two 90, with four side magazines, mixing from first two and bottom two.

- One 90 and two 72, with three side magazines, mixing from first two only.

- Two 90 and one 72, with three side magazines, mixing from first two only.

- Two 90, with two side magazines, mixing from first two.

- Two 90, with four side magazines. mixing from first two.

- Three 90, with three side magazines, mixing from first two and bottom two.

- Four 90, with two side magazines, mixing from first two, second two, third two.

- Four 90, with four side magazines, mixing from first two, second two, third two.

Surviving Machines:

#61651, #62791, #63151, #66070, #70200Model 31 | 1937

Single distributor machine called a Master Model.

This machine could be supplied in two styles. One style was the same as the Model 8 and could be supplied as a 1, 2, 3, or 4 main (split or full-length) magazine machine.

The other style was known as the Two-in-One and carried 72 and 90-channel magazines starting from two main magazines in combinations as follows:

Three 72 and one 90-channel magazine or vice versa, or two 72 and two 90-channel magazines or vice versa, or one 72 and one 90 or two 90 and one 72. Also, 72 or 90-channel magazines could be placed in any position.

The change of magazines was accomplished by a dial for selecting the proper channel entrance. These machines were known as Blue Streak models.

Surviving Machines:

#53981, #54860, #55348, #55542, #55543, #55649, #55710, #56044, #56413, #56524, #56997, #57110, #57255, #57349, #57444, #57557, #57907, #58077, #59512, #59520, #59625, #59750, #60172, #60527, #60964, #60974, #61133, #61153, #61401, #61583, #61836, #61838, #61969, #62124, #62334, #62558, #62824, #64112, #64916, #65126, #65368, #65441, #65521, #65584, #65667, #65855, #66073, #66081, #66184, #66347, #66371, #66465, #66495, #66528, #66551, #66594, #66604, #66793, #66968, #66969, #67080, #67210, #67370, #67436, #67441, #67593, #67722, #67797, #68024, #68040, #68078, #68124, #68134, #68687, #68814, #68895, #68945, #69248, #69711, #69965, #70024, #70184, #70213, #70735, #72124, #72796, #72987, #73320, #73707, (Missing Serial Number), (Missing Serial Number), (Missing Serial Number), (Missing Serial Number), (Missing Serial Number), (Missing Serial Number), (Missing Serial Number), (Missing Serial Number), (Missing Serial Number), (Missing Serial Number), (Missing Serial Number), (Missing Serial Number), (Missing Serial Number)Model 32 | 1938

Same as Model 31 only equipped with 1, 2, 3, or 4 side magazines.

This machine replaces the Model 14. Both models could be had as 42-em machines, also regular and low quadding, fixed indention, and 6-pocket mold disk at additional cost. Both models were supplied as 1, 2. 3, or 4 main or side magazine machines except in the 72-90 combination nation which starts with two main magazines.

Surviving Machines:

#52693, #53300, #53686, #56451, #61476, #62751, #67464, #67539, (Missing Serial Number)Model 33 | 1938

Equipped with 2 or 4 magazines carrying Special Extra Wide 72 and Extra Wide 90-channel main magazines. The 90-channel magazines carry 24 pt. normal faces and the 72-channel magazines carry 36 pt. faces.

The 72-90 feature machine requires a special channel entrance change when shifting from 90 to 72-channel magazines and vice versa and in addition there were other changes, five or six, necessary before matrices could be assembled.

Surviving Machines:

#64326, #67076, #67529, #68141, #70973, #72897, (Missing Serial Number)Model 34 | 1940

Same as Model 33, with 1 side magazine. Also supplied in the 72-90 feature.

Surviving Machines:

#65670Model 35 | 1941

This super display model was similar to the Model 33 except that it was a mixer machine. It carried the same extra wide 72 and extra wide 90-channel magazines as the Model 33 and it was our understanding that the Model 35 had the same type of channel entrance as was carried on the Model 33. This model carried two or four main magazines only.

Surviving Machines:

#65930, #69252, #70619, (Missing Serial Number)Model 36 | 1941

APL | 1932

Comet | 1950

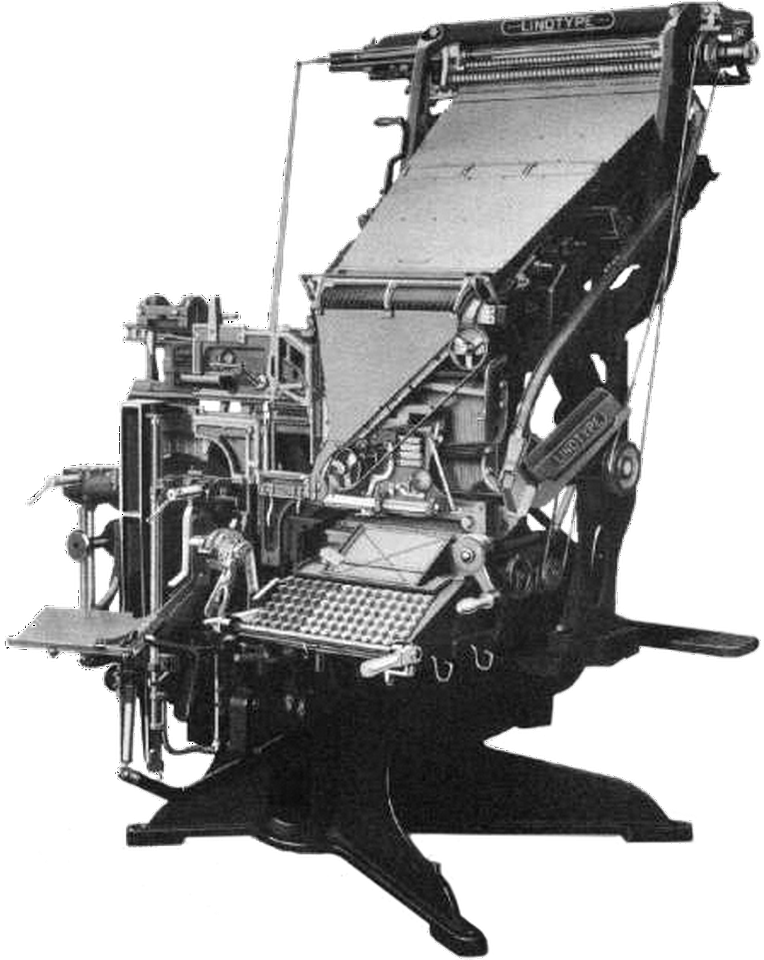

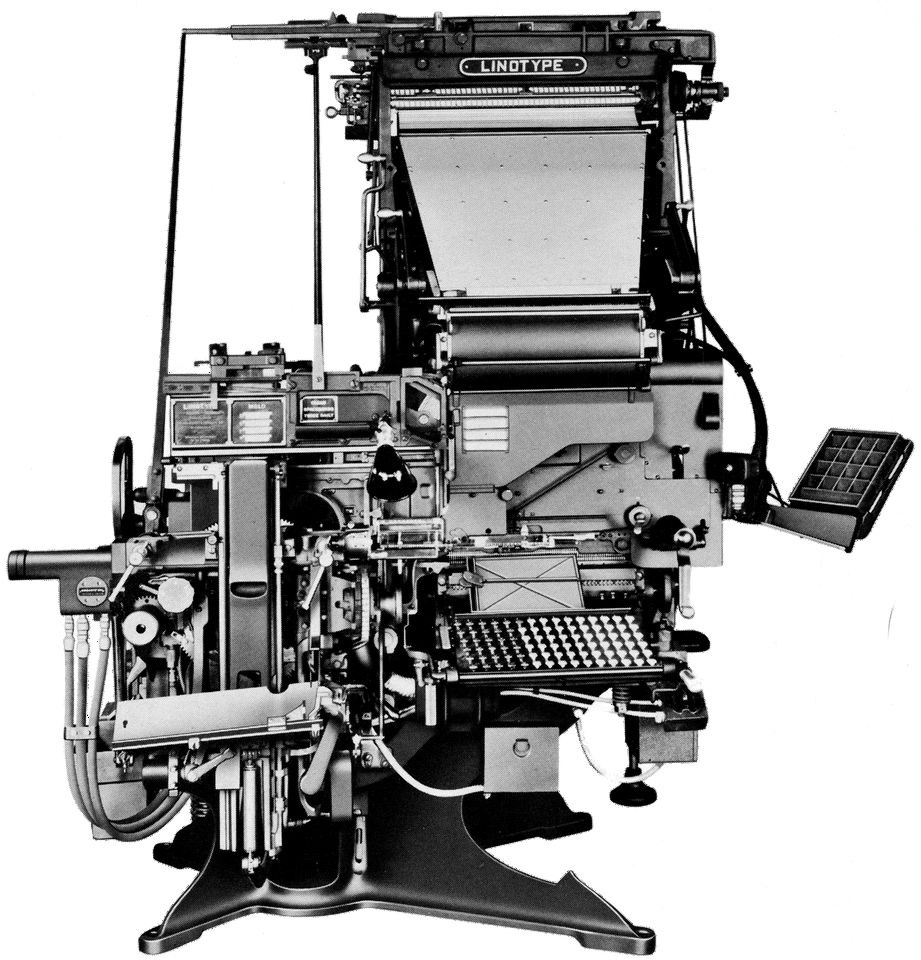

Model K | 1913

This machine was brought out for the purpose of meeting the competition of the Intertype. It was really, a rebuilt Model 1, but sometimes other models were rebuilt into, K's, and probably some of the machines were mostly new. The change of magazine was effected in much the same way as on the Model 8, but it was necessary for the operator to leave his seat. The upper magazine was removable from the front; the lower does not come off easily.

The escapement mechanism of the Model K had the same drawbacks as that of the Model 8. There were a large number of extra parts to get out of order and one more break in the string of connections between keyboard and verge.

The magazines were narrow, giving the machine the limited range of Models 1 and 10. Equipment of the Model K includes two fonts of matrices, two molds, (new), and a new set of spacebands.

There are no known surviving machines of this model.

Model X |

A Linotype converted into an Intertype by Intertype Corporation. While technically an Intertype, these machines initially shipped as Linotypes and carry Linotype serial numbers. Therefore they listed in the registry as Linotypes.

Surviving Machines:

#15527Model 54 | 1954

Surviving Machines:

#15843Model 78 | 1959

All linecaster photographs are licensed under the Creative Commons CC BY-ND 4.0 license. See https://creativecommons.org/licenses/by-nd/4.0/ for its terms. All portions of this document not noted otherwise are Copyright © 2022 Keelan Lightfoot. This work is licensed under the Creative Commons CC BY-SA 4.0 license. See http://creativecommons.org/licenses/by-sa/4.0/ for its terms.